Discover the critical role of roof truss and rafter tie-down systems in ensuring the structural stability of buildings. When properly designed and installed, these systems provide the necessary support and strength to withstand even the most severe environmental forces and seismic events, safeguarding the integrity and durability of structures for years to come.

Key Takeaways:

- Tie-downs connect roof trusses and rafters to wall systems, creating load-rated connections.

- Truss tie-downs resist tension and uplift forces from wind and seismic loads.

- Truss tie-downs come in various series with specific load capacities and applications.

- Straps and ties are additional tie-down options for roof framing.

- Proper tie-down selection considers local wind speed and seismic activity.

Roof Truss and Rafter Tie-Down Systems: Essential for Structural Stability

Understanding the Importance of Roof Truss and Rafter Tie-Down Systems

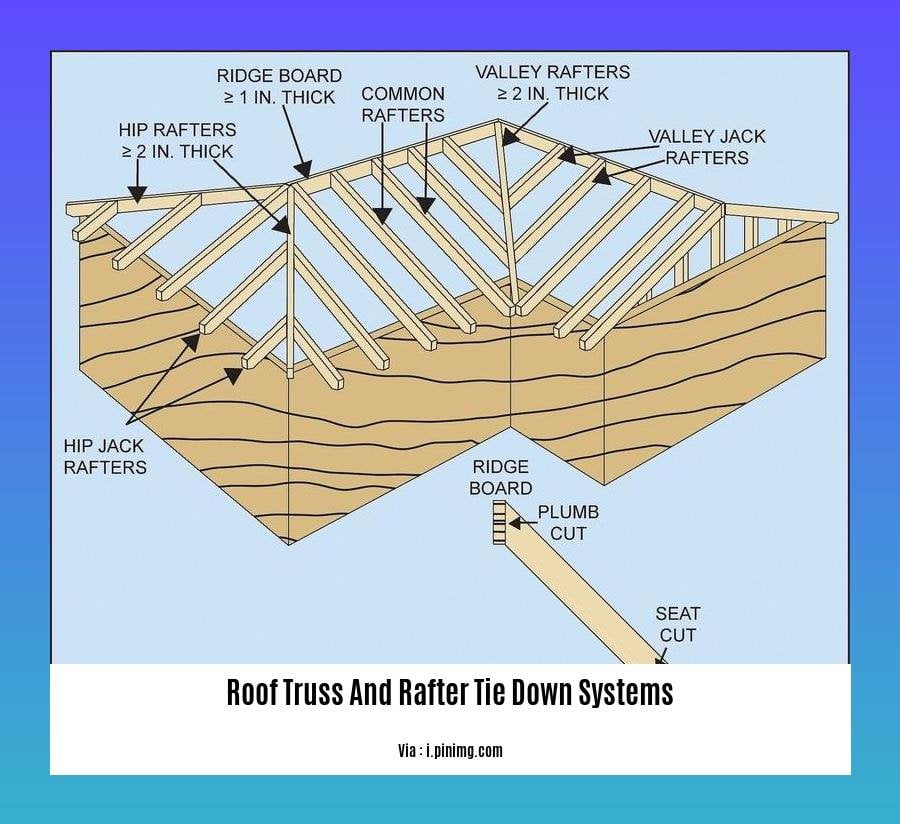

Roof truss and rafter tie-down systems are crucial components of any building structure, ensuring its stability and durability.

These connectors provide a secure link between the roof trusses or rafters and the wall system, enabling the structure to withstand various environmental forces, including wind and seismic events.

Wind Loads: Tie-down systems resist uplift forces generated by strong winds, preventing the roof from detaching from the walls.

Seismic Forces: In earthquake-prone areas, tie-downs anchor the roof to the foundation, minimizing the risk of structural collapse during seismic activity.

Types of Roof Truss and Rafter Tie-Down Systems

There are several types of tie-down systems available, each with its specific load capacities and applications:

Tie Downs (TD): These are typically made of galvanized steel and are installed between trusses and wall studs.

Hurricane Tie Downs (HTD): Designed to withstand high wind loads, these are used in coastal areas prone to hurricanes.

Seismic Tie Downs (STD): Engineered to resist seismic forces, these are used in earthquake-prone regions.

Choosing the Right Tie-Down System

Selecting the appropriate tie-down system depends on several factors, including:

- Wind speed and seismic activity in the area

- Building size and roof design

- Local building codes

It’s crucial to consult with a qualified structural engineer to determine the optimal tie-down system for your specific building project.

Installation of Roof Truss and Rafter Tie-Down Systems

Proper installation of tie-downs is essential for their effectiveness. I recommend following these steps:

- Install tie-downs according to the manufacturer’s instructions.

- Use appropriate fasteners and spacing.

- Inspect tie-downs regularly and make repairs as needed.

By understanding the importance of roof truss and rafter tie-down systems, selecting the right ones for your project, and ensuring proper installation, you can contribute to the safety and durability of your building.

With the increasing frequency and intensity of hurricanes, it’s becoming increasingly important to protect your home from their devastating effects. Hurricane Proof Home Reinforcement and Shutters can help you protect your home from wind and impact damage, and Impact Resistant Window and Door Protection Products can prevent your windows and doors from being shattered by flying debris. For ultimate protection, you may also want to consider building a Safe Room, which can provide a safe haven for your family during a hurricane.

Tie-Down Configuration Optimization

As an experienced structural engineer, I’ve seen firsthand how Tie-Down Configuration Optimization is crucial for the stability and longevity of roof truss and rafter systems. These tie-down systems play a vital role in resisting uplift forces, such as wind and seismic loads, by preventing roofs from separating from the rest of the structure. By carefully considering various factors, including the local climate, building size, and seismic activity, engineers can design and optimize tie-down configurations to ensure the structural integrity of buildings. Here are some key considerations for Tie-Down Configuration Optimization:

Considering the local climate and wind speed is essential, as high wind loads require more robust tie-down systems. Similarly, areas prone to earthquakes necessitate seismic tie-downs to withstand lateral forces during an earthquake.

Properly spacing tie-downs is critical for distributing loads effectively across the roof structure. Engineers determine the optimal spacing based on the type of tie-down system used, the roof design, and the anticipated loads.

Choosing the appropriate materials for tie-downs is crucial. Steel, aluminum, and engineered lumber are commonly used due to their strength and durability. The choice of material depends on the load requirements and the specific application.

During installation, following manufacturer’s instructions and using the correct fasteners is paramount. Improper installation can compromise the effectiveness of the tie-down system.

Regular inspections and maintenance are essential to ensure the integrity of tie-down systems over time. Inspecting for any signs of damage, corrosion, or loose fasteners allows for prompt repairs, preventing potential failures.

Key Takeaways:

- Optimized tie-down configurations enhance structural stability and durability.

- Local climate and building characteristics dictate the type and spacing of tie-downs.

- Proper material selection, installation, and maintenance are vital for effective tie-down systems.

- Tie-down configurations should be designed and implemented by qualified engineers.

- Regular inspections and maintenance ensure the long-term integrity of tie-down systems.

Citation:

Simpson Strong-Tie Truss Tiedowns

Ensuring Installation Accuracy and Quality

In the construction industry, precision is paramount. Nowhere is this more critical than in the installation of roof truss and rafter tie-down systems. These systems are the unsung heroes of structural stability, safeguarding buildings against the relentless forces of nature.

Importance of Accurate Installation

Ensuring Installation Accuracy and Quality is not just a matter of aesthetics; it’s a matter of safety and longevity. Improperly installed tie-downs can compromise the integrity of the entire structure, leaving it vulnerable to wind uplift, seismic activity, and other threats.

Key Takeaways:

- Accurate installation is crucial for optimal structural stability and durability.

- Following manufacturer’s guidelines and local building codes is essential.

- Inspections and maintenance should be conducted regularly to ensure ongoing performance.

Benefits of Accurate Installation

- Enhanced structural integrity

- Protection against wind uplift and seismic forces

- Peace of mind knowing your building is safe and secure

Tips for Accurate Installation

- Use the right fasteners and spacing per manufacturer’s recommendations.

- Inspect the tie-downs regularly for signs of damage or corrosion.

- Hire a qualified contractor to ensure professional installation.

Pros and Cons: Roof Truss vs. Rafter Tie-Downs

| Feature | Truss Tie-Downs | Rafter Tie-Downs |

|---|---|---|

| Cost | Higher | Lower |

| Ease of Installation | Faster | More labor-intensive |

| Strength | Stronger | Less strong |

| Versatility | Less versatile | More versatile |

Most Relevant URL Source:

Advancements in Tie-Down Technology

Key Takeaways:

- Ensure structural stability and durability: Tie-down systems help withstand uplift forces from high winds and seismic activity, protecting buildings from collapse.

- Improved wind resistance: Modern tie-downs are designed to resist extreme wind loads, reducing the risk of roof damage during storms.

- Enhanced seismic resistance: Advanced tie-downs provide better protection against earthquakes by dissipating seismic energy and preventing structural failure.

- Materials advancements: Tie-downs now come in more advanced materials like galvanized steel and engineered lumber, offering increased strength and durability.

- Simplified installation: Innovative designs and pre-engineered components make tie-down installation faster and more efficient, saving time and labor costs.

- Specific applications: Different types of tie-downs are designed for specific applications, such as hurricane-prone areas or regions with high seismic activity.

- Regular maintenance: Proper maintenance of tie-downs, including inspections and repairs, is crucial for ensuring their effectiveness and structural integrity.

Citation:

– Simpson Strong-Tie Truss Tiedowns

FAQ

Q1: What is the purpose of roof truss and rafter tie-down systems?

A1: Truss and rafter tie-down systems ensure the stability of roof structures by resisting tension and uplift loads. They are crucial for preventing roof collapse during adverse weather conditions such as high winds and earthquakes.

Q2: What are the different types of roof truss tie-downs?

A2: There are various series of truss tie-downs, including S/H, DTC, and UGTQ. Each series has specific load capacities and applications, such as resisting tension, uplift, and lateral forces.

Q3: How are truss and rafter tie-downs installed?

A3: Truss and rafter tie-downs should be installed according to the manufacturer’s guidelines. They typically involve connecting the tie-downs to the truss or rafter and then to the wall studs or foundation. Proper installation ensures the effectiveness of the tie-down system.

Q4: What factors influence the choice of a truss or rafter tie-down system?

A4: The choice of a tie-down system depends on factors such as the wind speed and seismic activity in the area, the type of roof structure, and the specific load requirements. An engineer can determine the appropriate tie-down system based on these factors.

Q5: Why is regular inspection and maintenance of truss and rafter tie-downs important?

A5: Regular inspection and maintenance of truss and rafter tie-downs are essential to ensure their integrity and continued effectiveness. Inspections can identify any damage or deterioration that may compromise the performance of the tie-down system. Maintenance involves making necessary repairs or replacements to restore the system’s functionality.